h3 { color: #CD2626; }

p2 { font-size: 80%; }

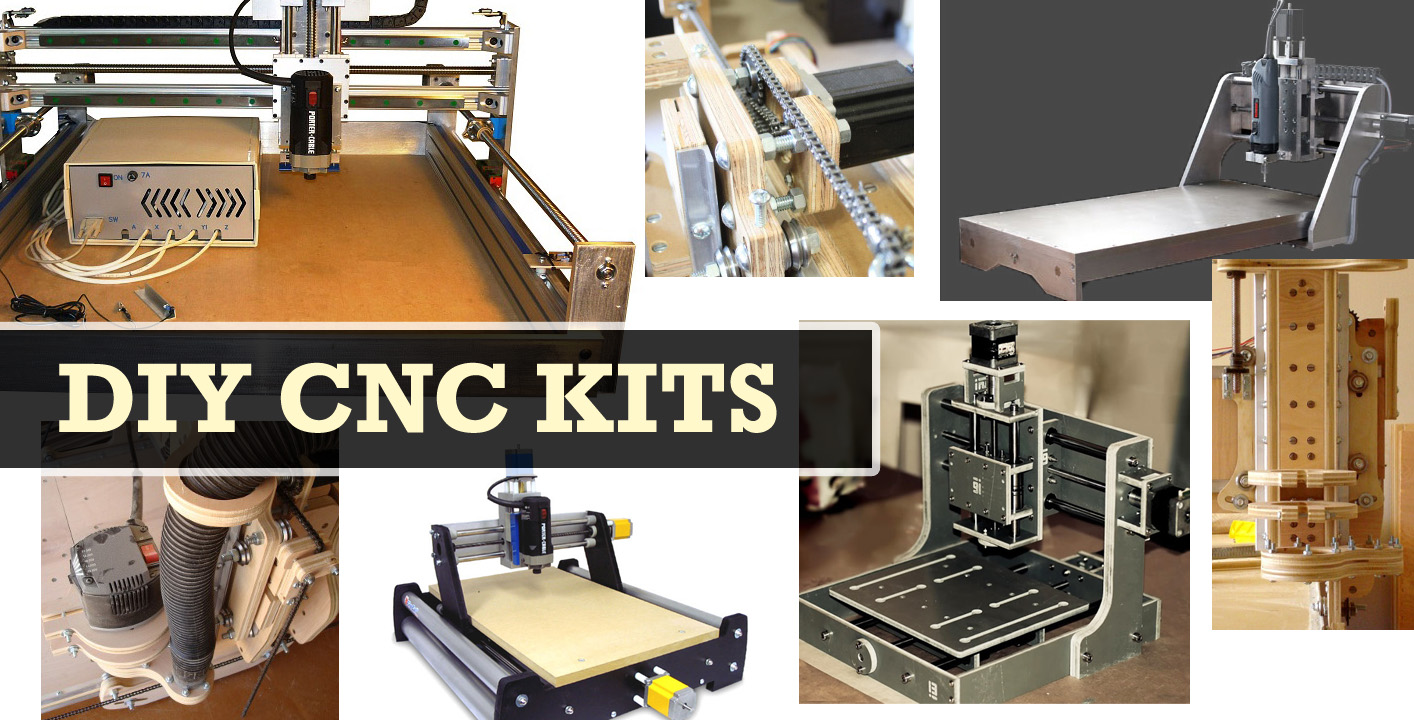

18 DIY CNC kits from mini to mega

Ponoko offers an online, on-demand CNC routing service where you can upload your design file and we’ll send you the CNC cut pieces.

Top 10 Tips To Reduce Laser Cutting Costs

Everything you need to know to reduce your laser cutting costs.

UPDATE: As of 18 February 2013, Ponoko is suspending its CNC routing service. But please check out our 3D Printing service and Laser Cutting service!

But we know that lots of you makers would like your own CNC machine. So I’ve put together this guide!

This is a pretty thorough guide with brief introductions, images, and links to 18 different do-it-yourself CNC kits available for purchase. I’ve tried to give the cost of the complete kit (not including shipping) next to each kit name, and kits are ordered lowest price first.

If you know of any other complete CNC kits available for purchase, please leave info in the comments.

Also, I couldn’t have put this list together without the wealth of information available at the excellent and very active CNCZone forums.

1. ShapeOko — $335

Resolution: n/a | Repeatability: n/a | Positional accuracy: n/a

Open hardware CNC & 3D printer kit.

ShapeOko is the result of a successful Kickstarter project, months of hard work, and lots of community support. It features extruded aluminum rails from MakerSlide, custom laser-cut steel plates, and an 8″x8″ cutting area with a Z axis height of 3.5″ The $175 kit comes with everything but the electronics. And there’s a super good wiki support page. :: ShapeOko

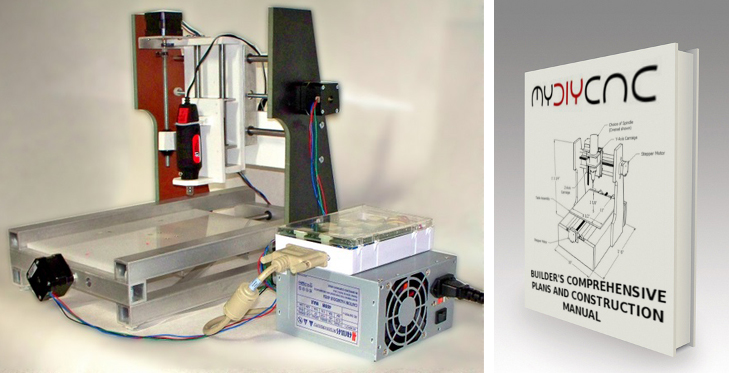

2. MYDIYCNC — $445

Resolution: n/a | Repeatability: n/a | Positional accuracy: n/a

Successful Kickstarter project now offers complete kit for under $500.

MYDIYCNC began as a Kickstarter project at the start of the year. The project was funded 465%, and now, nearly one year later, the MYDIYCNC is available for purchase. The kit is $445 and comes with the Construction Plans and Comprehensive Builder’s Manual (which can be purchased separately). A pre-assembled machine can be ordered for $580. :: MYDIYCNC

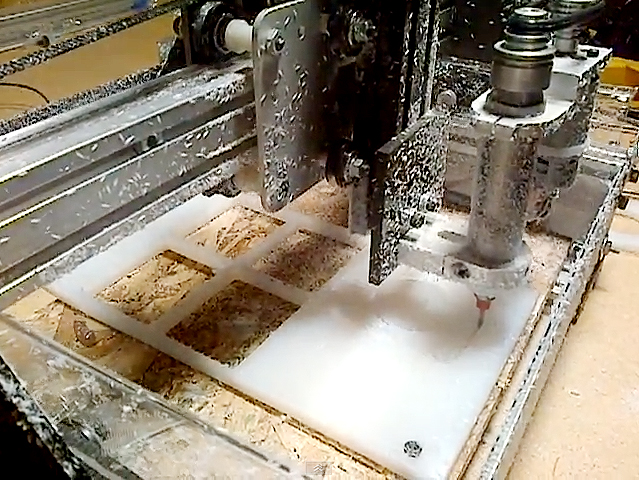

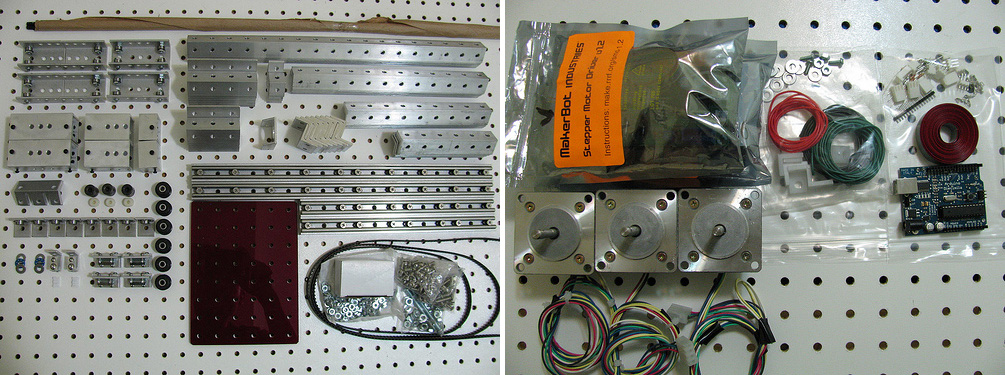

3. Contraptor Mini CNC — $500

Resolution: 8000 steps per inch | Repeatability: 0.01″ | Positional accuracy: 0.01″

Affordable & well supported project; perfect for beginners new to CNC.

Various Cartesian robots can be assembled from Contraptor: XY plotter, mini CNC mill, 3D printer etc. You can have a complete CNC by ordering the Mini CNC subset and the Electronics & Motors subset. This is an excellent site/project perfect for beginners new to CNC machines. There’s even a series of Google SketchUp tutorials for working with 3D models of Contraptor components. :: Contraptor

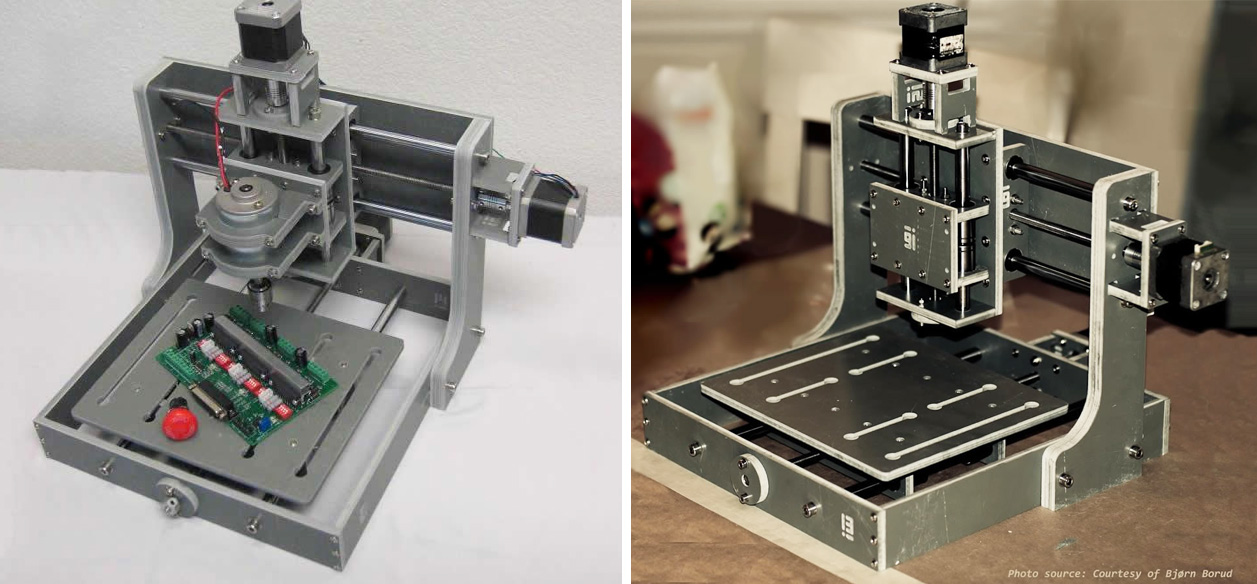

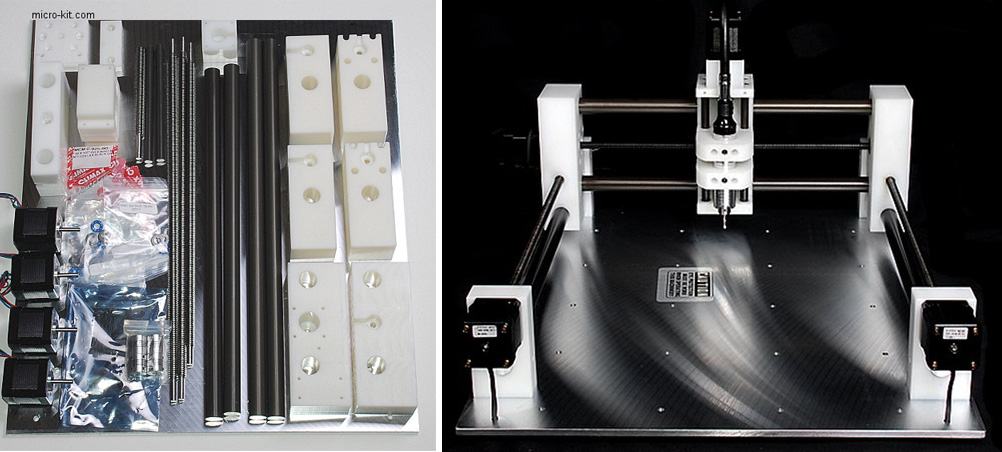

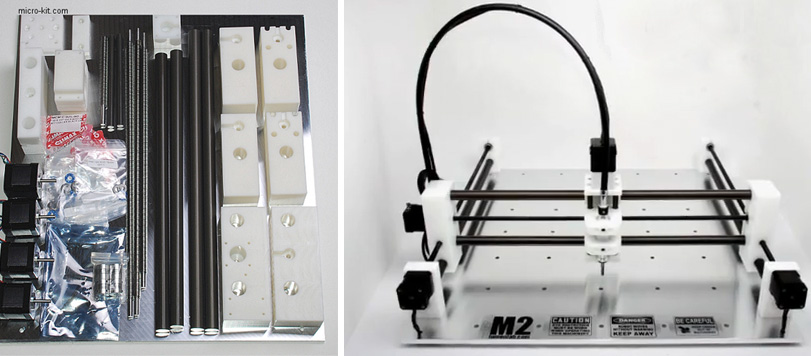

4. micRo-kit™ — $699

Resolution: 0.000052” | Accuracy: +/- 5% | Repeatability: +/-.001”| Positional accuracy: +/-.001”

Carve, print, and plot with this “precision fabrication system.”

This is the flagship CNC robot from Lumenlab. It’s a desktop machine that gives you a 12.75″ x 11.75″ x 3.75″ working area. You also get a lifetime warranty on the special “monolithic blocks” that come in the kit. Unlike the larger m3 kit listed further down, you do not have to drill your own holes into the base. :: Lumenlab

5. DIYLILCNC — $700

Resolution: XY – 0.004″; Z – 0.0003″

The kit is $225 and comes with lasercut panels only.

Hardware and electronics must be sourced separately and will run about $475, for a total of about $700. Cutting area is 10″x10″x2″. The DIYLILCNC is raising funds through Kickstarter for an improved version 2.0. :: DIYLILCNC

6. Zen Toolworks CNC 7×7 Complete Package — $756

Resolution: n/a | Accuracy: n/a | Repeatability: n/a | Positional accuracy: n/a

Includes everything you need and takes 3-4 hours to assemble.

You can get just the carving machine kit for $330, but this complete package comes with the kit, Mach3 CNC control software (licensed copy), 3 axis stepper motor driver board, power supply, spindle kit, emergency stop switch, and 6 limit switches. :: Zen Toolworks

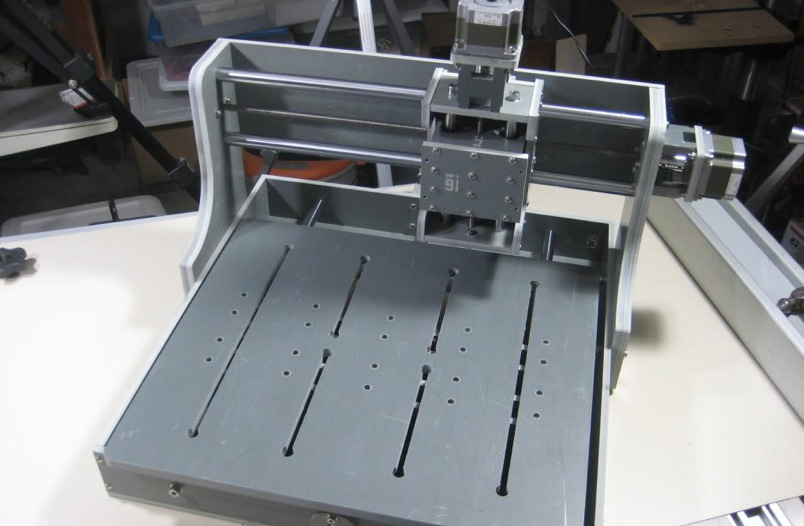

7. micRo m3-kit — $999

Resolution: 0.000052” | Accuracy: +/- 5% | Repeatability: +/-.001” | Positional accuracy: +/-.001”

A “precision fabrication system” for plotting, printing, and cutting.

This sleek looking machine comes with a lifetime warranty on micRo’s “unique monolithic blocks.” There’s a working area of 19 x 19 x 3.75 inches. And assembly will take several hours, especially since you’ll have to drill your own holes in the aluminum base. :: Lumenlab

8. Zen Toolworks CNC 12×12 Complete Package — $1,082

Resolution: n/a | Accuracy: n/a | Repeatability: n/a | Positional accuracy: n/a

Includes everything you need and takes 3-4 hours to assemble.

You can get just the carving machine kit for $600, but the complete package will get you the machine kit, spindle power supply with variable speed control, Mach 3 CNC control software (licensed copy), 3 axis stepper motor driver board, power supply and spindle kit. :: Zen Toolworks

9. WhiteANT CNC/3D printer — $1,060

Resolution: X Y – 39.37 steps per mm; Z – 314.96 steps per mm | Repeatability: Very good

The kit is $590 but you’ll need about $470 in parts from MakerBot.

There are videos for every step of assembly for this all-in-one 3D printer & CNC mill. But if you want to build one from scratch, you’ll need to buy the book. :: WhiteANT CNC/3D printer kit

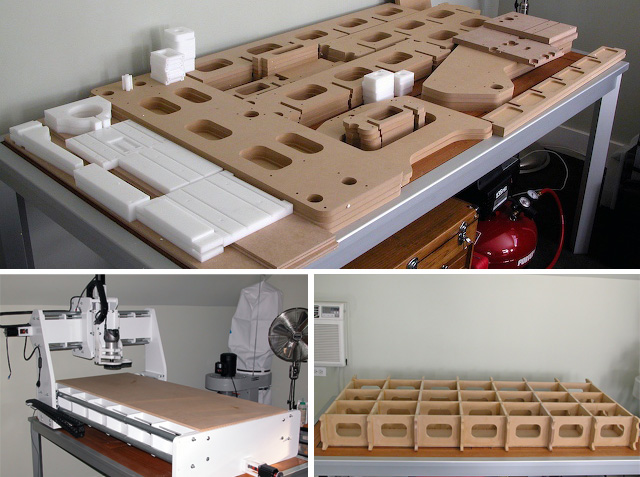

10. Joe’s CNC Model 2006 — $1,200

Resolution: n/a | Repeatability: Very good

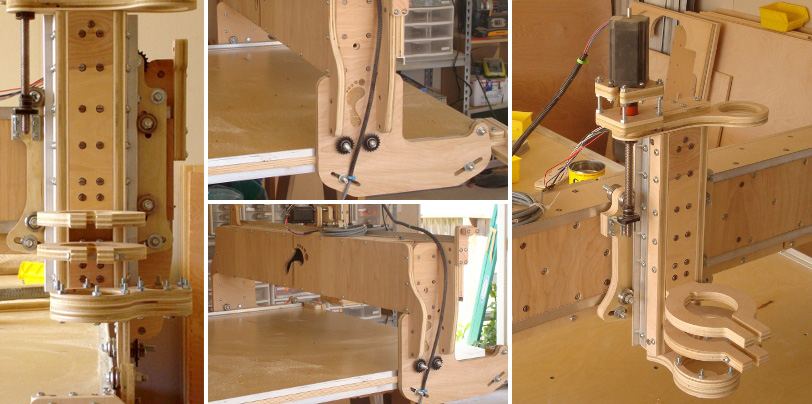

Kit is $550 and includes MDF and HDPE parts only.

This kit is made from durable high density polyethylene, medium density fiberborad, and some aluminum and steel parts. Cutting area is X:48″ Y:24″ Z:4.5″ Plans for Joe’s 06 CNC Router are open-source and free. :: Joe’s CNC

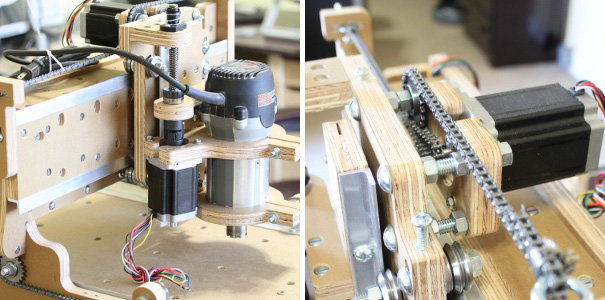

11. blueChick version 4.2 — $1,525

Resolution: 1422.222 steps per inch | Repeatability: Very good

All you need and a 12″x36″ cutting area. 3″ on the Z.

This latest version of the blueChick is an improvement over version 3.0 (which is still available for $1,385). Version 4.2 provides an alternative drive method, a relocation of the x-axis motor, a beefed up gantry structure, reduction in the overall height of the machine plus a roller chain drive mechanism. :: blueChick 4.2

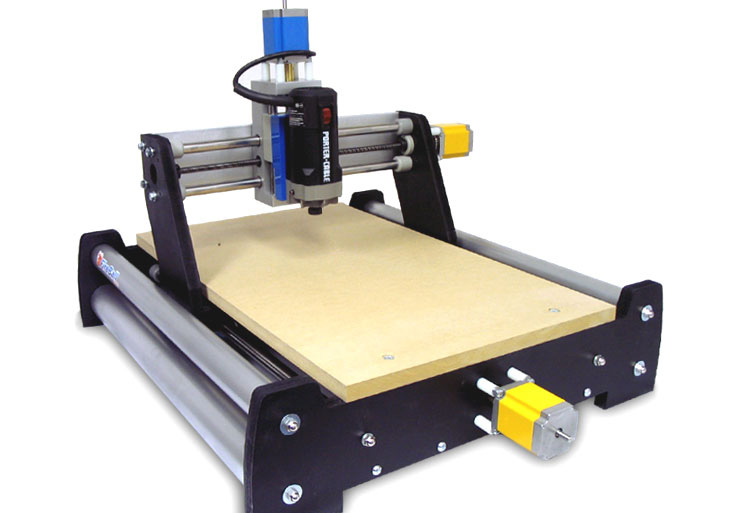

12. FireBall V90 — $1692

Resolution: 0.001″ (full step)

A base kit is $600; the best options and upgrades total $1692.

You get a 12″x18″x3″ cutting area and assembly is apparently just an hour. MeschCam 3D CAM software is bundled with the FireBall V90 for $99. And there’s a Yahoo group for support. :: FireBall V90

13. blackToe 2’x4′ — $2300

Resolution: 1422.222 steps per inch | Repeatability: Very good

There’s an optional table for $300, and you can get the kit w/o electronics for $1910.

This isn’t a desktop CNC mill, but a full on piece of garage equipment. As the website says, “Version 4.0, a solid, fast, attractive chain driven CNC machine. … The overall structure is solid with respect to stresses in all directions. … Chain drive for this CNC machine will allow velocities into the 800 to 1000 ipm (inches per minute) range.” :: blackToe 2’x4′

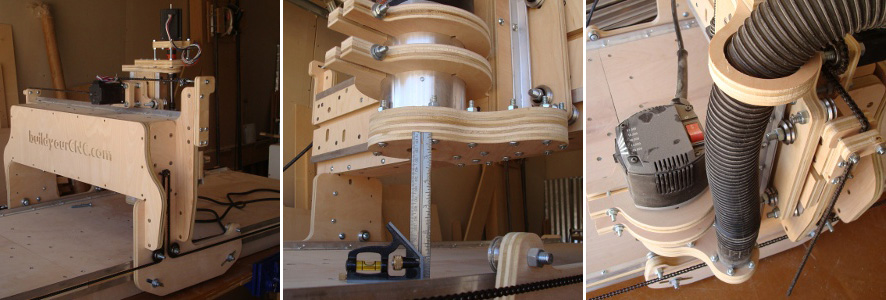

14. blackFoot 4’x8′ — $2,863

Resolution: 1422.222 steps per inch | Repeatability: Very good

Software, router, and table not included.

The blackFoot is functionally and aesthetically impressive. There are 2 router mount sizes and the roller chain provides excellent precision. You can cut aluminum, wood, plastic, steel, etc. There are other purchasing options for the blackFoot as well, including just the plans ($400), just hardware & electronics ($1383) and just the hardware ($923) :: blackFoot 4’x8′

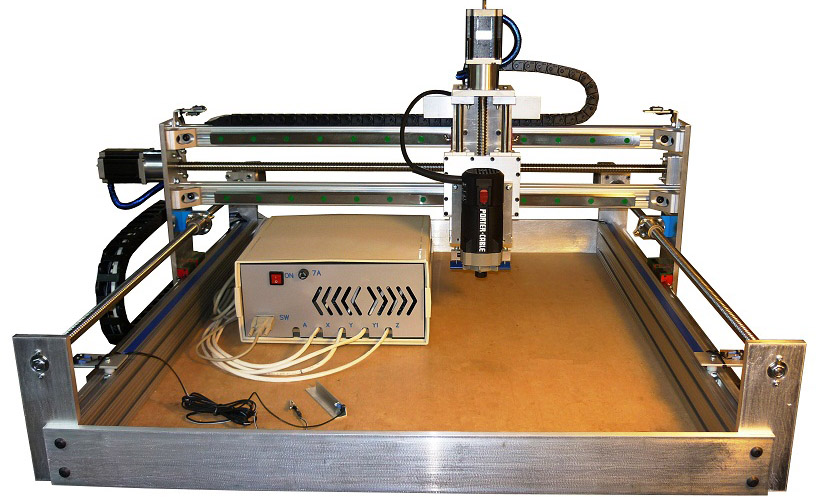

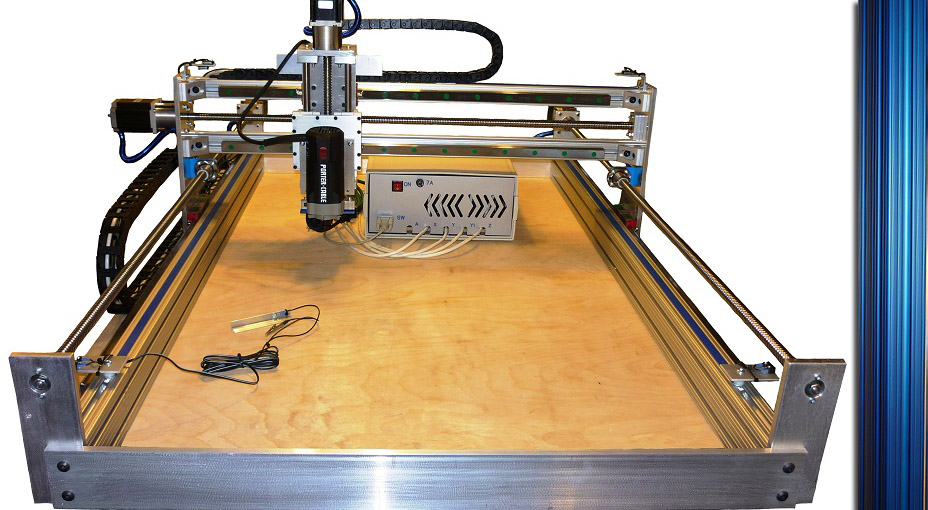

15. Pilot Pro Ex 2626DIY — $3,750

Resolution: 200 steps\rev | Accuracy: Typical| Repeatability: <0.015mm | Positional accuracy: 10160 steps per inch

Made from milled aluminum and there’s an option for blue anodizing.

This all metal design gives you a cutting area of 26″x26″x4.5″ and comes with everything you need — hardware, software, and electronics. You can also get a pre-assembled machine for about a thousand bucks more. :: Pilot Pro Ex 2626DIY

16. Pilot Pro Ex 2642DIY — $4,250

Resolution: 200 steps\rev | Accuracy: Typical| Repeatability: <0.015mm | Positional accuracy: 10160 steps per inch

A bigger version of the Pilot Pro Ex featured above.

Also made entirely of metal, this larger machine gives you over 60% more room on the Y axis. And you can get a pre-assembled machine for $5,200. The 2642 + blue anodizing option on the aluminum shown below. :: Pilot Pro Ex 2642DIY

17. Badog X2 — $6,117

Resolution: n/a | Accuracy: n/a | Repeatability: n/a | Positional accuracy: n/a

A powerful compact machine cuts virtually any material.

The Swiss made Badog X2 kit comes with everything you need including their own Badog CAD/CAM software, but “can be used with almost any other control software on the market”. :: Badog CNC Suisse

18. Badog X3 — $10,399

Resolution: n/a | Accuracy: n/a | Repeatability: n/a | Positional accuracy: n/a

Comes with an extra 4th axis motor. Cuts pretty much anything.

For 4th axis control you’ll nedd Mach3 software which can be downloaded for free on the Badog site. Definitely a pricey piece of equipment but all pieces are milled in-house — *on this machine*. :: Badog CNC Suisse

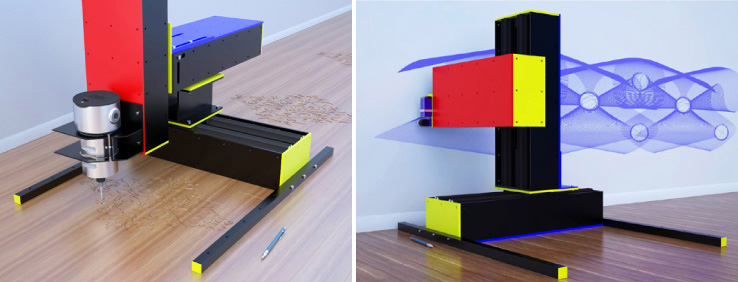

Bonus: RedBlueCNC — n/a (student project)

A mobile, modular CNC mill with various mounting configurations.

RedBlueCNC is graduate student project from Nick Santillan. It was a finalist in the James Dyson Awards and is currently in the running for a Core 77 Design Award. Read more about the versatility of this CNC mill. (It really is unlike any other CNC machine out there.) It’s not available as a kit, but it definitely should be! Good luck at the Core 77 Awards. :: RedBlueCNC

And now for a bit of self-promo: If you want to make stuff with CNC routing but don’t want to own the machine, you can use Ponoko’s online CNC routing services to have the pieces shipped to your door. To make your own CNC designs with Ponoko, sign up for a free account and download our 2D design starter kit.

UPDATE: As of 18 February 2013, Ponoko is suspending its CNC routing service. But please check out our 3D Printing service and Laser Cutting service! You can learn more by signing up for a free Ponoko account.

12 Comments

Nooo ! You forgot the contraptor mini-cnc !!!

Contraptor.org

Hi Arthur, I just visited this page: http://www.contraptor.org/order-beta-kits

I’m happy to add it to my list. Can you tell me if you would need to order all the subsets in order to have a complete mill?

A good list with a few that I haven’t seen before.

Any chance of listing tolerances. For me that’s at least as important as price and work area.

(Shame you apparently can’t even see a BOM for Joes CNC without paying. Though correct me if I’m wrong.)

Hi Steve. Thanks for the suggestion. I’ll go through and try to find and list all of the tolerances. And I did not see a list of materials for Joe’s CNC, but perhaps it can be found somewhere on the CNCZone forums.

Nice list with quite a few that I haven’t seen before! I found two models you didnt have listed though. They are the from Lumenlab, the micro($699 as a kit) and the m3($999 as a kit).

Check them out at http://www.lumenlab.com

Steve is right, accuracy/repeatability is a key factor in determining whether these devices are useful machines or just toys. And you need a figure determined by testing not just calculation based on stepper motor resolution. For machines that dead-reckon position from stepper motor position (rather than using scales) the tolerance and backlash in the lead screws needs to be included. In machines using Dremel tools as cutters I have seen significant play in the spindle assembly itself, and in the mounting of the tool to the machine. It would not surprise me if the overall accuracy of some of the cheaper machines was 0.040in or worse.

A few I forgot in my earlier comment;

There’s the all aluminium Sable 2015 available from http://www.cnc-sable.nl or eBay.

Also IEHC has a lot of machines starting at $1200.

aren’t you forgetting this one…

http://www.instructables.com/id/How-to-Make-a-Three-Axis-CNC-Machine-Cheaply-and-/

I have designed a 4’x8′ open source CNC gantry router called the Kikori:

http://www.kickstarter.com/projects/1738994529/kikori-open-source-cnc-gantry-router

I designed this machine to not only be very accurate, but also to be much more rigid than other similar machines. This allows it to maintain a much higher degree of accuracy while cutting faster and deeper, significantly reducing milling times.

First- awesome list, thanks for including us (lumenlab, that is)! However, both the V3 and M3 *are* pre-drilled for the X axis motor mounts. What we charge extra for is the grid drill pattern available for ease of fixturing.

Hello Robin. On the webpage for the m3 kit, it says “What you do: • drill 12 holes in the aluminum base (drill bit and drill guide included in kit)” … So you do not have to do any drilling? Just want to clarify before changing the post. Thanks for your comment!

A milling machine is a machine tool used to machine solid materials. Milling machines are often classed in two basic forms, horizontal and vertical, which refers to the orientation of the main spindle. Both types range in size from small, bench-mounted devices to room-sized machines. Unlike a drill press, which holds the workpiece stationary as the drill moves axially to penetrate the material, milling machines also move the workpiece radially against the rotating milling cutter, which cuts on its sides as well as its tip. rical control (CNC).

Comments are closed.