presentation for the 2011 RAPID conference

Last week I presented one of the Consumer Products talks at RAPID 2011. Several people approached me afterwards and asked for a copy, so I’ve decided to share it here on the blog. View and download the PDF here.

Here’s an abbreviated version (14 instead of 36 slides) of my 30 minute talk.

And because the conference was about additive manufacturing, the presentation focuses on 3D printing.

I started out by giving some context around the maker movement and explaining that a handful of new companies, all launched within the past 2-4 years, are helping people create their own products.

Industrial design in a digital making world

Everything you need to know about designing an industrial product for a factory of the future.

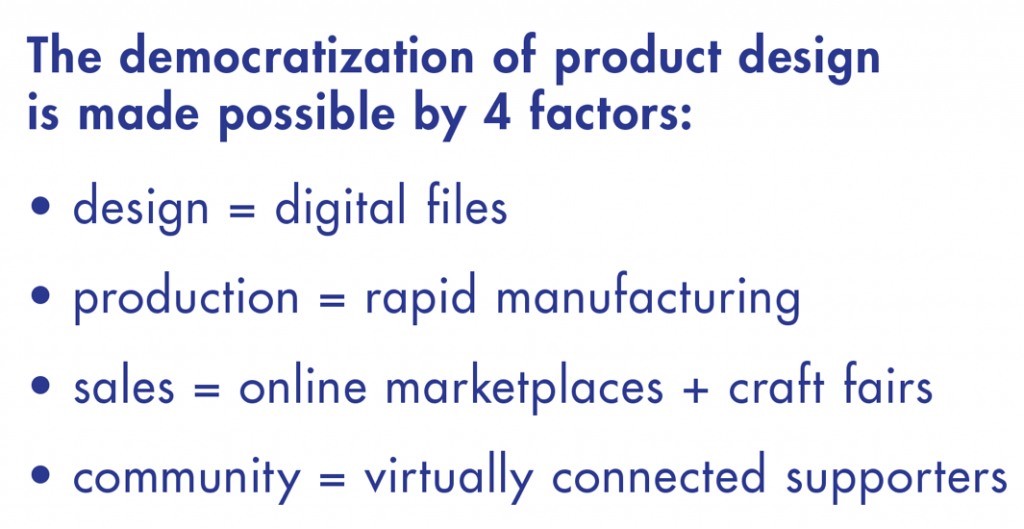

Then I outlined the 4 factors that make the democratization of design possible.

DESIGN: Products can be created, stored, and transported as digital files.

PRODUCTION: Digital fabrication technology turns digital design files into physical objects.

SALES: Online marketplaces, e-commerce software, and craft fairs let anyone price and sell their goods.

COMMUNITY: Blogs, social media, email, and meetups make marketing free and fun.

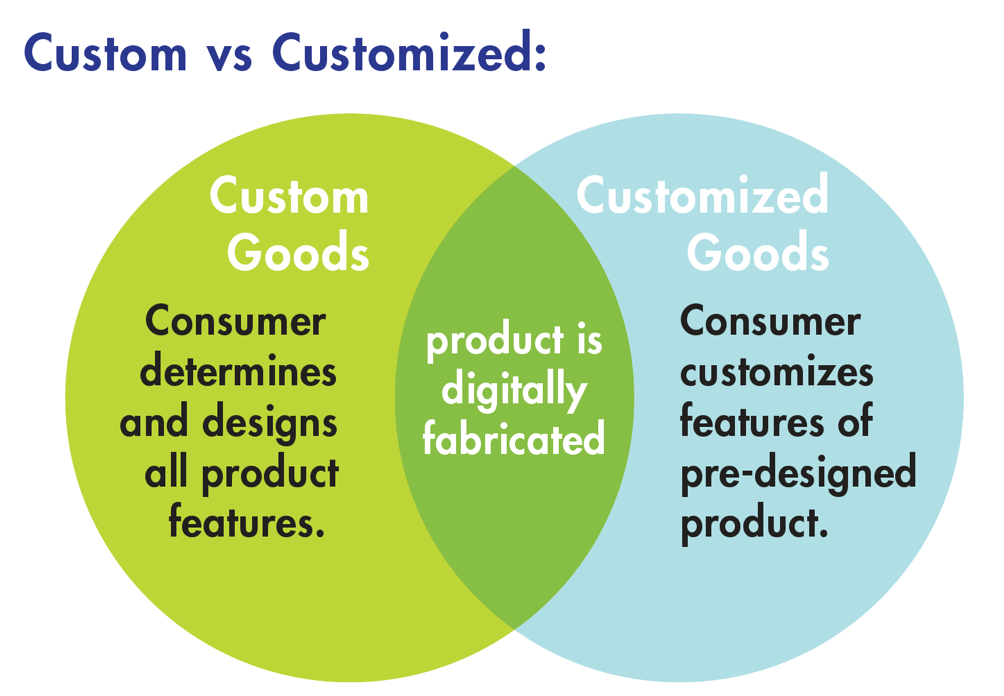

I explained that the democratization of product design was happening 2 ways: the creation of Custom goods and the creation of Customized goods.

In both cases, goods can be produced with 3D printing — either on a personal 3D printer or via outsourcing to a 3D printing service.

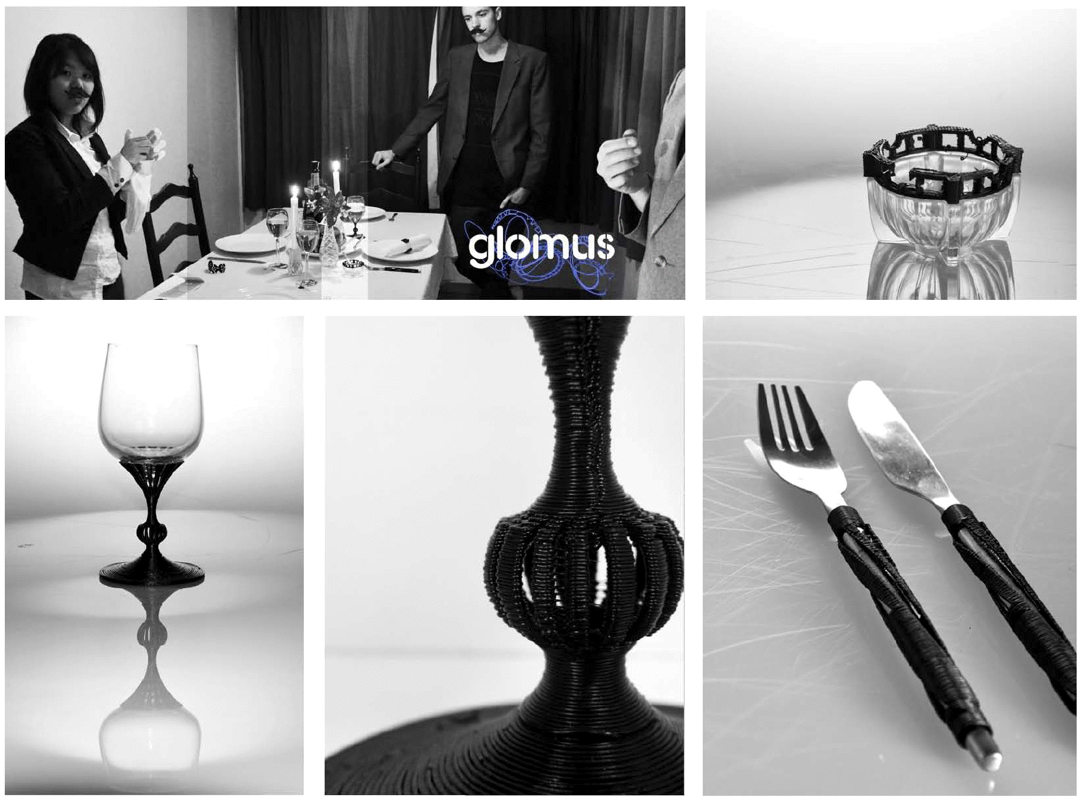

My first example of custom goods was a project by Glomus, a group of industrial design students, to rehabilitate broken and discarded objects of mass-manufacture with 3D printed ‘product prostheses’.

They used a MakerBot Cupcake CNC to bring new life to what had been tossed in the garbage — a broken wine glass is repaired with a 3D printed stem, a discarded bowl is turned into an ashtray, new handles are printed for a set of flatware. (Looks pretty good for a DIY 3D printer!)

My second example told the famous story of the Glif — how two guys with no industrial design experience and no start-up capital created a wildly successful iPhone accessory.

Going back to the 4 factors that make the democratization of product design possible:

DESIGN: Dan Provost and Tom Gerhardt first made a digital 3D model from their sketches

PRODUCTION: Then they ordered a 3D printed prototype from Shapeways and refined the design.

SALES: They used Kickstarter to raise funds for mass-production of their design and created 3D printed versions for their $50 backers.

COMMUNITY: Tech and maker blogs supported the project immediately. And long story short, they met their goal of $10,000 in under 1.5 hrs. When the month of funding ended, over 5,200 people had given over $137,000.

My final example of custom products looked at 3D printing as just one tool which could be combined with other digital fabrication technologies to create almost anything.

Ponoko lets you develop products using 3D printing, laser cutting, and electronic hardware. Each part of the product (except the electronic hardware) is fabricated on demand, allowing for the creation of custom products that let people *customize* parts of the product.

Above you see a furniture set created with CNC routing and a 3D printed and lasercut lamp sitting on the table. By tweaking the design files, people created customized versions of this lamp, shown below.

This lead me into 3 examples of customized goods, the creation of which takes no design skill.

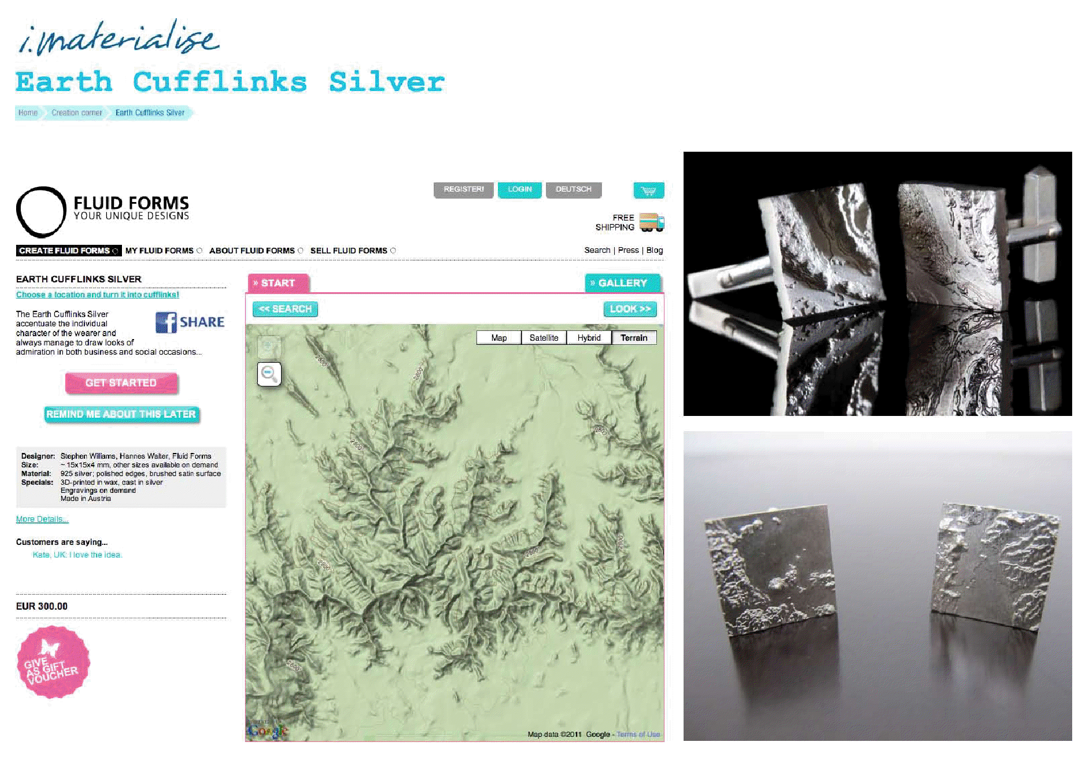

Fluid Forms, working with i.materialise, lets you customize a range of products including these 3D printed silver cufflinks.

By using data from Google maps, Fluid Forms lets consumers choose a favorite topography to be the design. (My map selection shows the Badlands in South Dakota.)

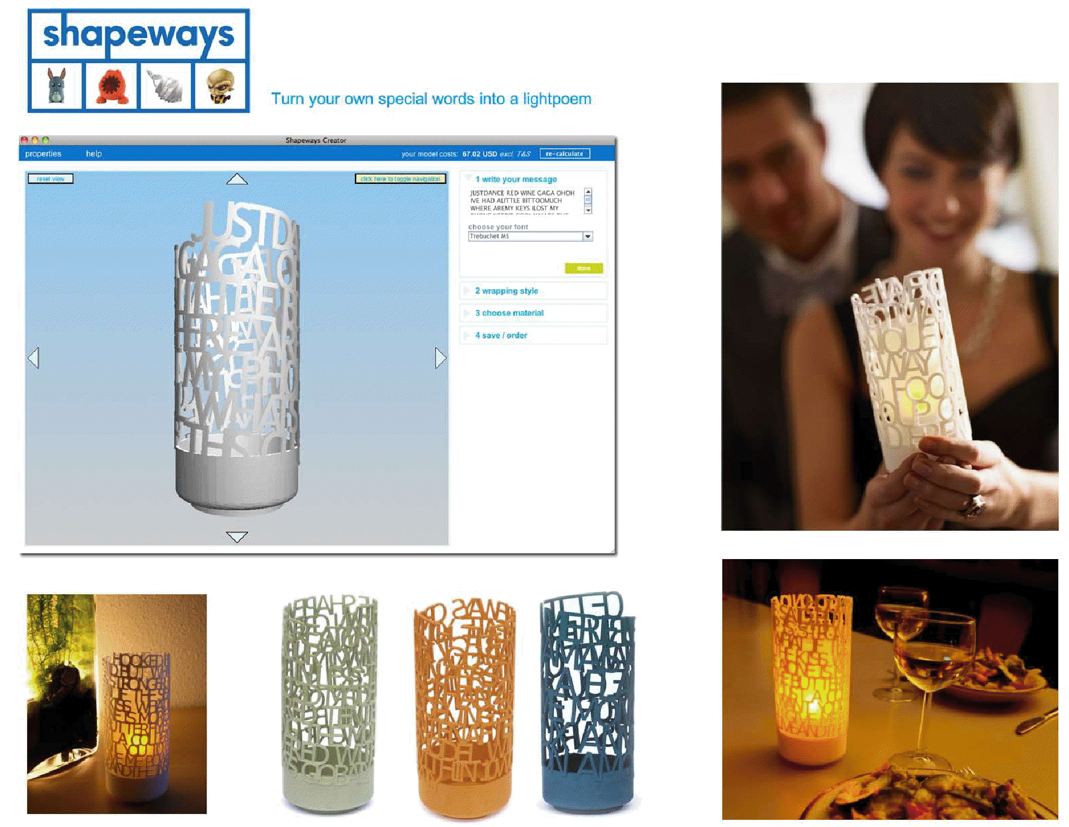

The lightpoem from Shapeways is a customizable lamp that lets consumers type the design.

An applet that run on the consumer’s computer renders a 3D model that changes in real time based on each letter typed. Then the consumer just choses a material and color and orders a 3D printed product.

For my last example, I looked at Ponoko’s approach to mass-customization — the recently announced App Gateway.

Developers can create ‘making apps’ that are integrated with Ponoko, giving people access to not only 3D printing, but laser cutting and CNC routing as well — directly from an app.

The first app available is 123D from Autodesk. It’s a free, 3D modeling tool that lets users design from scratch or start from one of the many pre-made starter designs. A “make” button is built right into the app and lets consumers get their model made.

Finally, I touched on what makes making so compelling to people and what ‘make-it-yourself’ means for the product design and product retail industry.

Thank you to everyone who came up to talk to me after the presentation. RAPID was honestly more fun than I expected.

You can read a brief summary of each of the other consumer products talks, check out an overview of the RAPID expo, and see the 3D printed artworks from the gallery.

3 Comments

Thanks for offering this comprehensive schematic of the history of this exciting trend. Though many view the democratization and globalization of technology and info fearfully — the whole idea excites me to no end personally.

Creative people never cease to amaze and inspire me, and this summary underlines this strongly. Let’s all go and make things!

This is fantastic, Kristen. A really digestible overview. Thanks for sharing!

Thanks for a really good overview of how digital manufacture is changing not only how product is designed and manufactured but also how the customer is able to engage with on-line tools and participate in the creative process.

It’s extraordinary to think that it’s still ‘early days’ for this emerging industry, the potential of which is yet to be fully realised, but it already seems to be capturing peoples imagination in a way that encourages them to change everything!

Comments are closed.